Our Location

No.2 Zhongxing Road, Chenchong Industry Zone, Longjiang Town, Shunde District, Foshan City, Guangdong P.R China.

In the field of furniture manufacturing, plenty producers make the similar or same look, providing a wide choice of different needs for user. Table bases, even client can see the material, still many factors will make difference on quality and price.

Starting from the structure of a table base, basically there are mounting plate (top plate, conjunction of base and top), column, bottom base.

Mounting

This part is most time invisible, but the size, material and weight are highly related to the material of tabletops and using places. Most producers do a post forming square mounting plate with steel, size between 250-350mm, saving the cost of molding and material. Lifepursue has wide choice by cast iron, aluminum for 300 – 550mm with folding option.

Column

Most straight shape column is able to change heights and customize heights for coffee, dining, counter, bar. Round dia 60mm, 76mm, square 80*80mm is the common spec. ornamental tubes in poseur look of cone, vintage, flute will have to use molding which results in higher cost and large quantity for starting production.

Bottom base

The shape and stability are the most important part. Round or square shape is equal in all directions on stability. Cross base provides free space. Whatever the shape is, material and width (or diameter) is the fundamental factor for loads. From experience, one-half or two-thirds of the tabletop is the suitable match for the bottom. There are also adjustable glides underneath for balancing.

Construction by thread rod that fasten the table base providing extra stability.

The column that attaches between mounting and bottom, most producers do welded assembly. It’s an easy way for producing and assembly. Thread rod throughout the column provides better stability and durability.

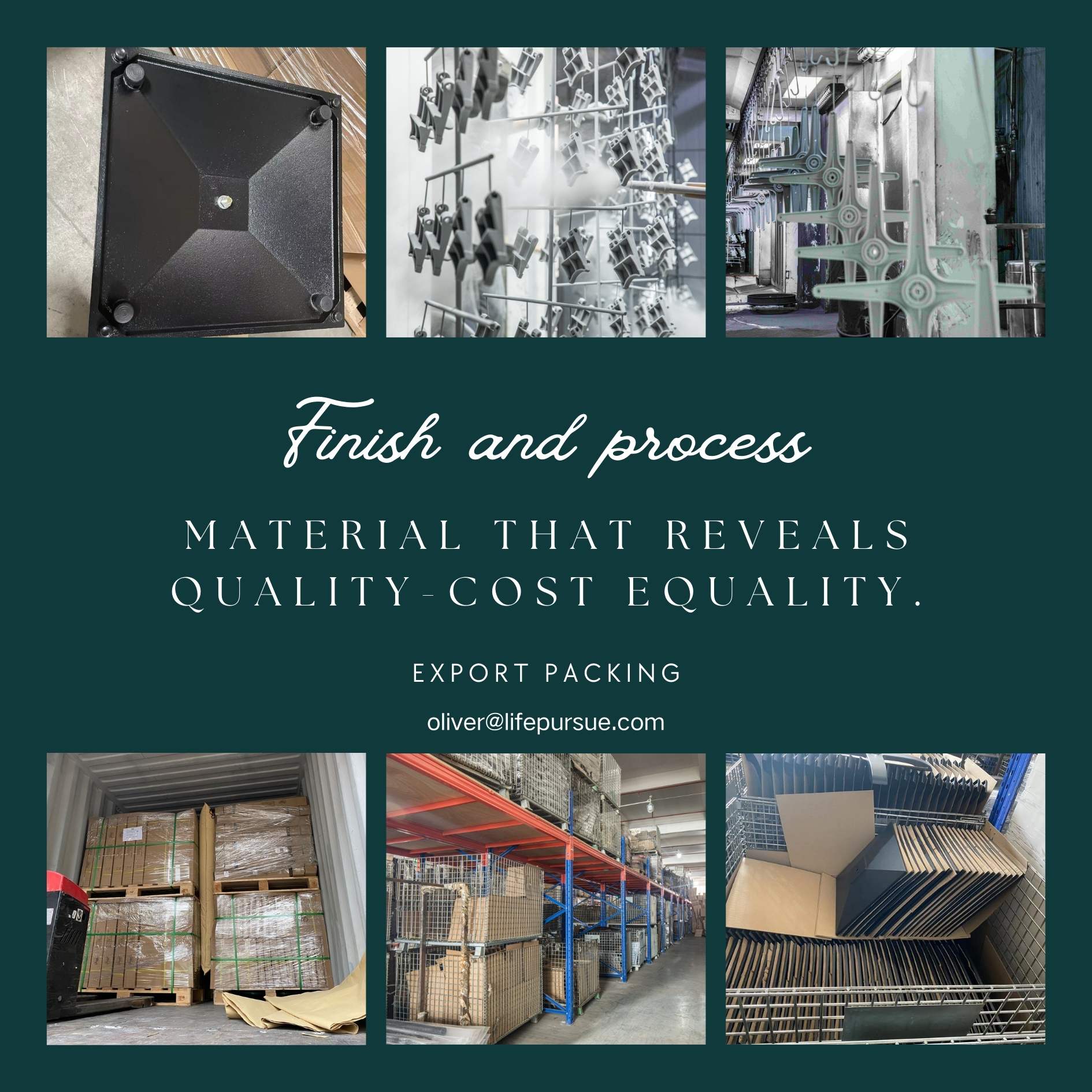

Surface process and finish

Powder coating is an important step for surface finishing. We used high-grade powder; clients can customize color per RAL code. We have more than 450M powder coating lines. The imported nano-coated filter element with a high filtration accuracy. The surface look can be processed to matte, sand, glossy, brushed, polished per exact demands of project needs.

Material that reveals quality-cost equality.

Cast iron and steel is the first choice for interior use, these metal table bases are heavy self-weight, durable and stable. But when the environment being moist, frequently contacting liquid, stainless steel, aluminum, cement will have better experience. Especially aluminum is a great choice for lighter weight and rust resist. Those material originally has price gaps between producers, compare only from price regardless of metal thickness, product weight and grade is hard to generate fair judgements.

Good package is a warranty for long way delivery.

Lifepursue standard exporting 5ply corrugated KD carton and Bubble wrap & foam holder with Nylon cable ties. Optional wooden pallet or crate for forklift loading and dispatch. Reduced the problems caused by packaging.

When choosing a table base supplier for the projects of hospitality and commercial venues, clear thoughts in front of low price is decisive.

Lifepursue team of professionals can do more than just picking a design that blend with surrounding atmosphere and décor, also take these considerations for selective products both functional satisfaction and aesthetically appealing.